Check all article List - Best Sewing Machine | Review of All Sewing Machine | Sewing Tips | Textile | Accessories | How to

The sewing machine is an essential tool for anyone who likes to sew, whether as a hobby or as a profession. It allows people to create their clothes, repair damaged garments, and personalize their garments with embroidery and appliques. However, to keep the machine running smoothly and efficiently, it is important to maintain it regularly, and in this sense, lubrication is one of the most important steps.

Lubricating your sewing machine is essential for maintaining its efficiency and longevity. Here’s a simple guide on how to clean a sewing machine:

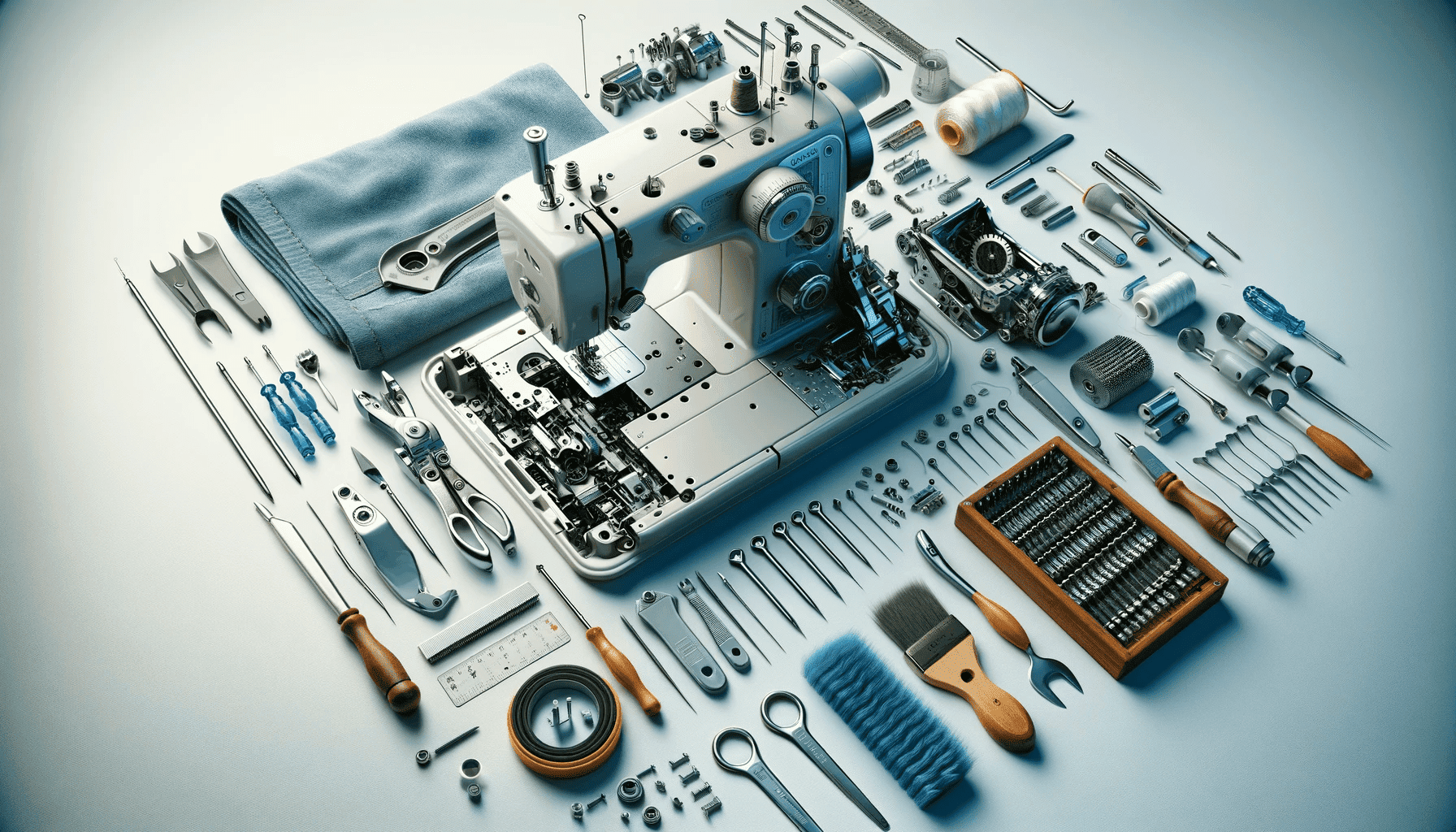

Steps to Clean a Sewing Machine

- Read the Manual: Always start by referring to your sewing machine’s manual. Different models may have specific lubrication requirements and recommendations.

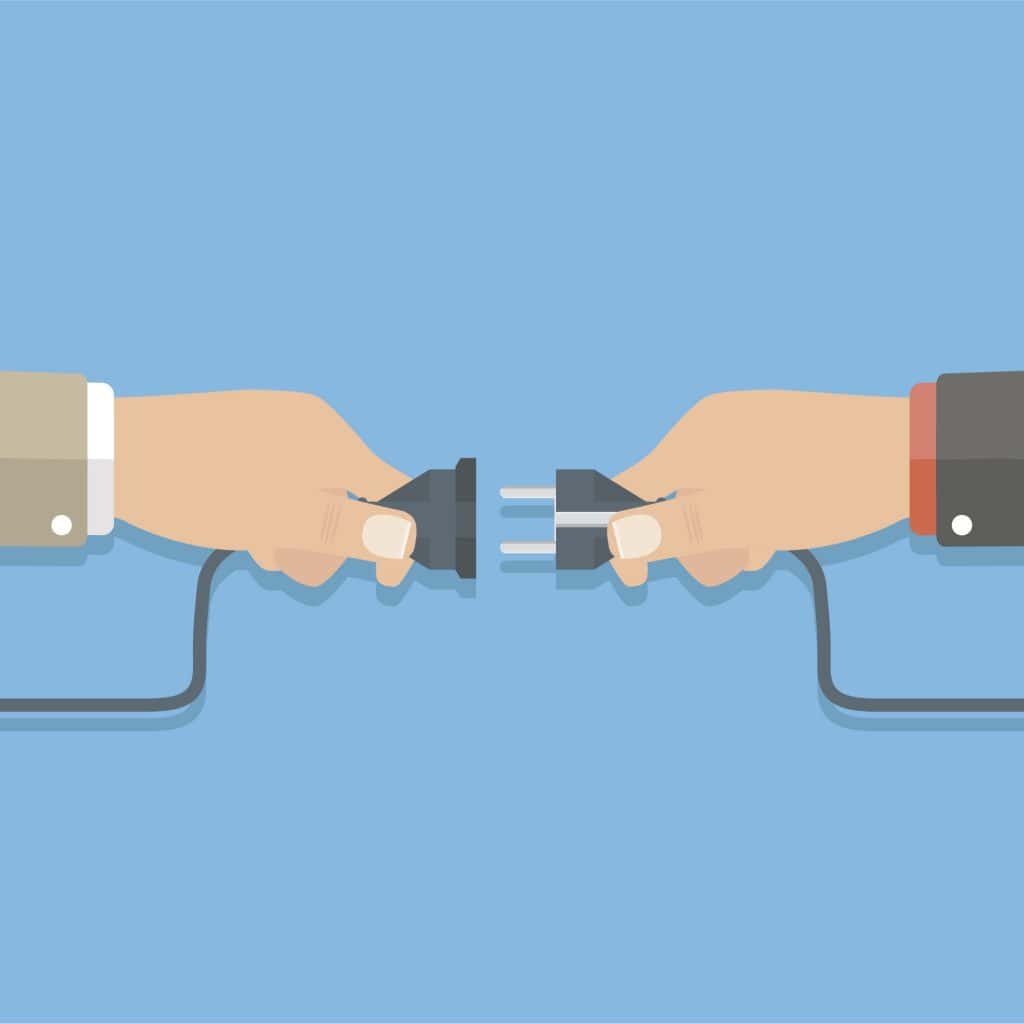

- Disconnect the Machine: Safety first! Unplug the machine to avoid any electrical hazards.

- Clean the Machine: Before lubricating, clean any dust, lint, or debris from the machine. Use a small brush or a vacuum cleaner with a brush attachment to clean around the bobbin case and under the needle plate.

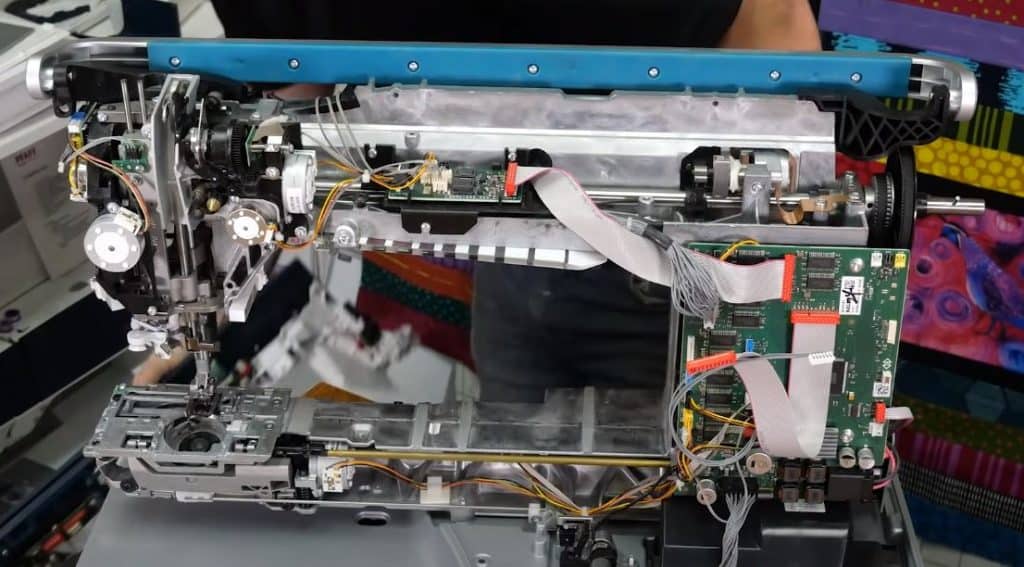

- Identify Lubrication Points: Consult the manual to find out where to apply oil. Common lubrication points include the bobbin case area, moving parts of the needle mechanism, and any other areas as specified by the manufacturer.

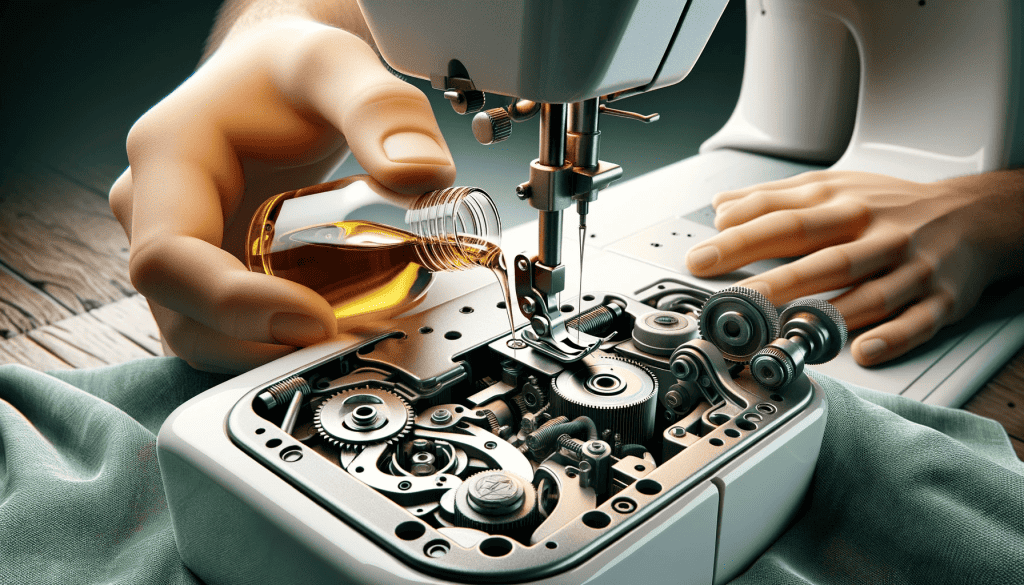

- Apply Sewing Machine Oil: Use only oil specified for sewing machines. Apply a drop or two of oil to each of the points indicated in the manual. Avoid over-lubricating as it can attract dust and lint.

- Distribute the Oil: Gently turn the handwheel or run the machine at a slow speed to distribute the oil through the moving parts.

- Wipe Excess Oil: After lubricating, wipe away any excess oil with a soft cloth to prevent it from staining your fabric.

- Test the Machine: Plug in the machine and test it on a scrap piece of fabric. Check for smooth operation and make sure there are no oil stains.

Additional Tips

- Frequency of Lubrication: The frequency of lubrication depends on how often you use the machine. A good rule of thumb is to Clean after every 8 hours of use or at least once a month if used regularly.

- Type of Oil: Always use oil specifically designed for sewing machines. Other types of oil can be too thick or thin and may damage the machine.

- Regular Maintenance: Regular cleaning and lubrication are key to keeping your sewing machine in good working order.

These are crucial initial steps in the process of lubricating a sewing machine:

Disconnect the machine from the Power Source:

- Safety First: Before you begin any maintenance on your sewing machine, always ensure it is turned off.

- Unplug the Machine: Remove the plug from the electrical socket. This step is essential to prevent any risk of electric shock or accidental activation of the machine while you’re working on it.

Remove Dirt and Lint Buildup:

- Clean Thoroughly: Over time, sewing machines can accumulate dust, lint, and debris, especially in areas around the bobbin case and under the needle plate.

- Use a Small Brush or Vacuum Cleaner: A small, soft-bristled brush is ideal for gently removing lint and dust from delicate machine parts. Alternatively, a vacuum cleaner with a brush attachment can efficiently remove debris from harder-to-reach areas.

- Pay Attention to Specific Areas: Focus on the bobbin area, feed dogs, and beneath the needle plate, as these are common places where lint builds up.

- Regular Cleaning: Regularly removing dirt and lint not only facilitates smoother operation but also ensures that the oil you apply can effectively Clean the moving parts without getting gummed up with debris.

Apply Oil to the Bobbin Area

- Access the Bobbin Area:

- Unscrew and remove the bobbin cover to expose the bobbin case.

- Apply Lubricating Oil:

- Use a high-quality sewing machine oil.

- Apply a few drops of oil to the bobbin area, specifically targeting the coil.

- Be cautious with the amount – a few drops are usually sufficient. Over-lubricating can lead to excess oil staining your fabric.

- Spread the Oil Evenly:

- Use a clean, lint-free cloth to gently spread the oil around the area.

- Ensure even distribution without leaving excess oil.

Clean Other Areas of the Machine

- Identify Key Lubrication Points:

- Refer to your sewing machine’s manual to locate specific areas that need lubrication. Common points include needle bars, gears, and other moving parts.

- Apply Oil to These Areas:

- Place a small drop of oil on each of these points.

- Use a clean cloth to spread the oil evenly, ensuring it reaches into the moving parts.

- Avoid Over-Lubrication:

- Like with the bobbin area, be careful not to overdo it. Excess oil can attract lint and dust, which can hamper the machine’s performance.

Additional Tips:

- Frequency of Lubrication: Regular lubrication is key. The frequency can depend on how often you use your machine. A general guideline is to oil the machine after every 8-10 hours of use.

- Type of Oil: Always use sewing machine oil. Do not use general-purpose oils or WD-40, as they can damage the machine.

Wipe Off Excess Oil

- Clean the Machine: After lubricating, it’s important to remove any residual oil. Excess oil not only makes the machine greasy but can also attract lint and dust, which may interfere with its functioning.

- Use a Clean Cloth: Take a clean, dry, lint-free cloth and gently wipe off any excess oil from the surfaces of the machine, particularly around the areas where you applied the oil.

- Be Thorough: Make sure to check all the nooks and crannies where oil might have accumulated. This includes the bobbin area, under the needle plate, and around any gears or moving parts you’ve cleaned.

Test the Machine

- Reconnect the Power: Once you’re sure that all excess oil has been removed, plug the machine back into the power source.

- Run a Test: Turn on the machine and run a few test stitches. Choose a scrap piece of fabric for this purpose.

- Check Stitch Quality: Pay attention to the quality of the stitches. They should be even and smooth, without any skipping or bunching.

- Listen for Unusual Noises: While testing, listen for any unusual sounds. The machine should run more smoothly and quietly after lubrication.

- Address Any Issues: If you notice any anomalies in stitching or hear unusual noises, turn off the machine. Recheck the areas you’ve cleaned to ensure there’s no excess oil and that all parts are moving freely.

- Regular Check-Ups: Regular testing and maintenance after lubrication help in the early detection of any issues and keep your sewing machine in optimal condition.

Following these steps ensures that your sewing machine is not only well-cleaned but also clean and ready for your sewing projects. Regular maintenance, including proper lubrication and testing, is key to the longevity and efficient performance of your sewing machine.

Conclusion on how to clean a sewing machine:

- Consult the Manual: Always start by referring to the sewing machine’s manual for specific instructions related to lubrication points and recommended oil types.

- Safety First: Disconnect the machine from the power source to ensure safety during the lubrication process.

- Clean Before Lubricating: Remove any dirt, dust, or lint from the machine using a small brush or vacuum cleaner, particularly around the bobbin case and other moving parts.

- Apply the Right Oil: Use only high-quality sewing machine oil. Apply it sparingly to the specified parts, such as the bobbin area, needle bars, gears, and other moving components as per the manual.

- Avoid Excess Oil: Wipe off any excess oil with a clean cloth to prevent it from attracting dust and lint.

- Regular Testing: After lubricating and cleaning, test the machine on a scrap piece of fabric to ensure smooth operation and consistent stitch quality.

- Follow a Maintenance Schedule: Adhere to a regular lubrication schedule. The frequency can vary based on the sewing machine model and usage intensity – some machines need oiling after each use, while others may require it after a set number of hours of operation.

Final Thought

In conclusion, lubricating your sewing machine is a vital maintenance task that significantly contributes to its efficient operation and longevity. Proper lubrication reduces friction between moving parts, prevents corrosion, and enhances stitch quality. To ensure effective lubrication:

Remember, regular lubrication is not just about immediate performance improvements; it’s a long-term investment in the health and durability of your sewing machine. By following these steps, you can enjoy seamless sewing experiences and maintain your machine in top condition for years to come.

Frequently Asked Questions (FAQ):

Here are some frequently asked questions about cleaning a sewing machine:

How often should I clean my sewing machine?

It is recommended to clean your sewing machine regularly, preferably after each completed project. This will help keep the machine running properly and producing quality seams.

Can I use a vacuum cleaner to clean my sewing machine?

It is not recommended to use a vacuum cleaner to clean your sewing machine, as this may damage its components. Use a soft-bristled brush to carefully remove dust and debris.

Can I use any type of sewing machine oil to lubricate my machine?

No, it is important to use the sewing machine oil recommended by your machine manufacturer. Using another type of oil may impair the machine’s operation.

What should I do if my sewing machine is still having problems after cleaning?

If your sewing machine is still having problems after cleaning, you may need to take it to a technician who specializes in sewing machine repair.

Check all article List - Best Sewing Machine | Review of All Sewing Machine | Sewing Tips | Textile | Accessories | How to